Modular Electrical Substation

Modular Electrical Substation

General

The Substation Generally is Manufactured in steel Profile and Corrugated sheets Completely Welded, Endowed of Certified Insulation Spread also to Doors and Openings for Fire Resistance when Needed and IP Degree to Satisfy any Harsh Environmental Condition from very High to very Low Temperature.

All Systems Produced and Inspected by BSS can Satisfy Customers’ Requirements and Reduce the Time and Cost Required for Installation and Pilot Operation.

All Systems Produced and Inspected by BSS can Satisfy Customers’ Requirements and Reduce the Time and Cost Required for Installation and Pilot Operation.

Electrical & Major Equipments

- MV Switchgears up to 36 kV

- LV Switchgears : Power Center, MCC : Motor Control Center

- LV Auxiliary Panel

- Explosion Proof Control Panels

- PLC Control Panel

- SCADA

- PMS

- AC / DC UPS

- VFD

- HVAC

- Fire Fighting System

- F & G

- ESD

Modular Power Supply Business

Electrical Substation Disadvantages

- Physical Size of the Operation

- Environmental Conditions

- Long Operational Hours

High-risk Area, Insufficient Expandability

-

Fast to Deploy

-

Reliable & Safety

-

Easy to Upgrade

Modural Electrical Substation

-

Modular Design

Saves Time, Money

Ensures Personal Safety

-

Customizable

-

Easy Installation

-

Pre-fabricated

-

Pre-tested

-

Optimized Cost

Specification

- Switchgear

- MV & LV Equipment

- MCCs

- Intelligent Meters

- Transformers

- UPS, Batteries

- HVAC, Fire & Lighting Equipment

- Pre-assembled in a Controlled Environment

- Easily Integrated

- Maximum Protection for Equipment

- Flexibility in Design and Upgrading

- Energy Monitoring and Control System

- Remotely Control Equipment

- Extensive Support Services

- Consultation and Maintenance Services

- Reduced Installation Time

- Complete Safety of Operations

Design Basic

※ Scroll Left / Right to Check the Contents.

| ITEM | SPECIFICATION | REMARK |

|---|---|---|

| ENVIRONMENTAL CONDITION | Operating Temperatures | -20℃ ~ + 50℃ |

| Relative Humidity | Up to 90% | |

| Climate Range | Hot Desert Climate ~ Clod Arctic Climate | |

| Wind Velocity | Up to 40㎧ (140㎞/h) | |

| Snow Loads | Up to 1 Meter of Snow | |

| Seismic Loads | Specific to Site, up to 0.18g | |

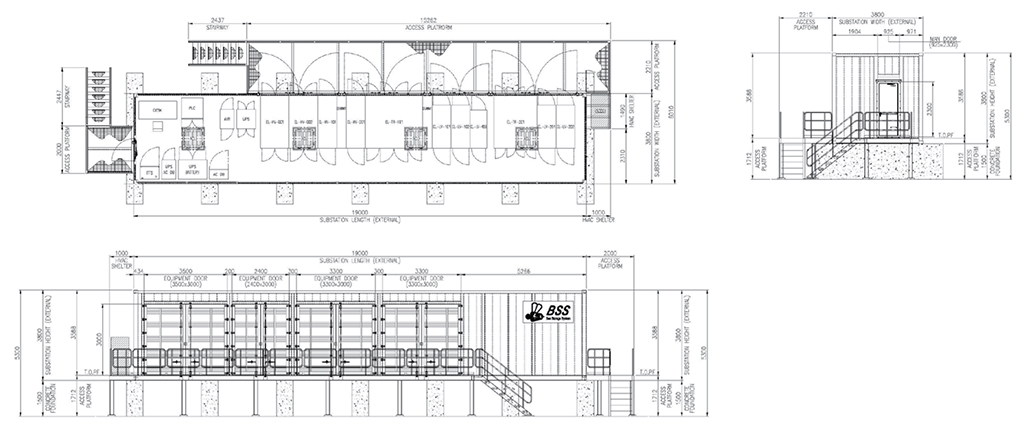

| BUILDING CONSTRUCTION | Dimensions | Building Dimensions are Designed in Accordance with Customer Spec. |

| Ambient Overpressure | Customer Request and Specification Application | |

| Insulation u-value | < 0.5 w/㎡/k | |

| Ingress Degree of Protection for Enclosures | Up to IP54 Grade(Non-Certificate, Water Spray Test) | |

| Fire Resistance | Customer Request and Specification Application | |

| Blast-resistance Building Design | Customer Request and Specification Application | |

| Rust and Corrosion Protection | Zinc-rich Painting Cycle with 275 μm Dry Coat Hot Dip Galvanizing |

Basic Concept Design

Basic Concept Design

※ Scroll Left / Right to Check the Contents.

| DESCRIPTION | ACTIVITY | SOW | REMARK | ||

|---|---|---|---|---|---|

| Client | BSS | ||||

| Engineering | Main Electrical Equipment | Switchgear, Transformer, UPS, Battery | |||

| Detailed Design(Structural, Elect., HVAC, Architecture, Fire Alarm System) | Including Substation GA, Structure Calculation | ||||

| Structural Analysis & Calculation | |||||

| Shop Drawing | |||||

| Procurement | Bulk | Steel / E & I / Architecture | Cable, Conduit, Tray, Etc. | ||

| Equipment | HVAC | ||||

| Major Power Generation Eequipment | Including HV & LV Switchgear, Transformer, UPS, Battery, PCS, DC PANEL, PMS / EMS, Etc. | ||||

| Fire Suppression, F & G | |||||

| Lighting / Heating / Ccommunication | |||||

| Construction | Production, Assembly, System Integration | Include Tagging Item | |||

| Test & Punch Clear | |||||

| Pre - Commissioning | Major Equipment and HVAC, Fire Alarm | ||||

| Load - Out | Packing and Shipment Preparation | ||||

| Load-out (FOB BSS Yard) | |||||

| Transportation | |||||